-

Description

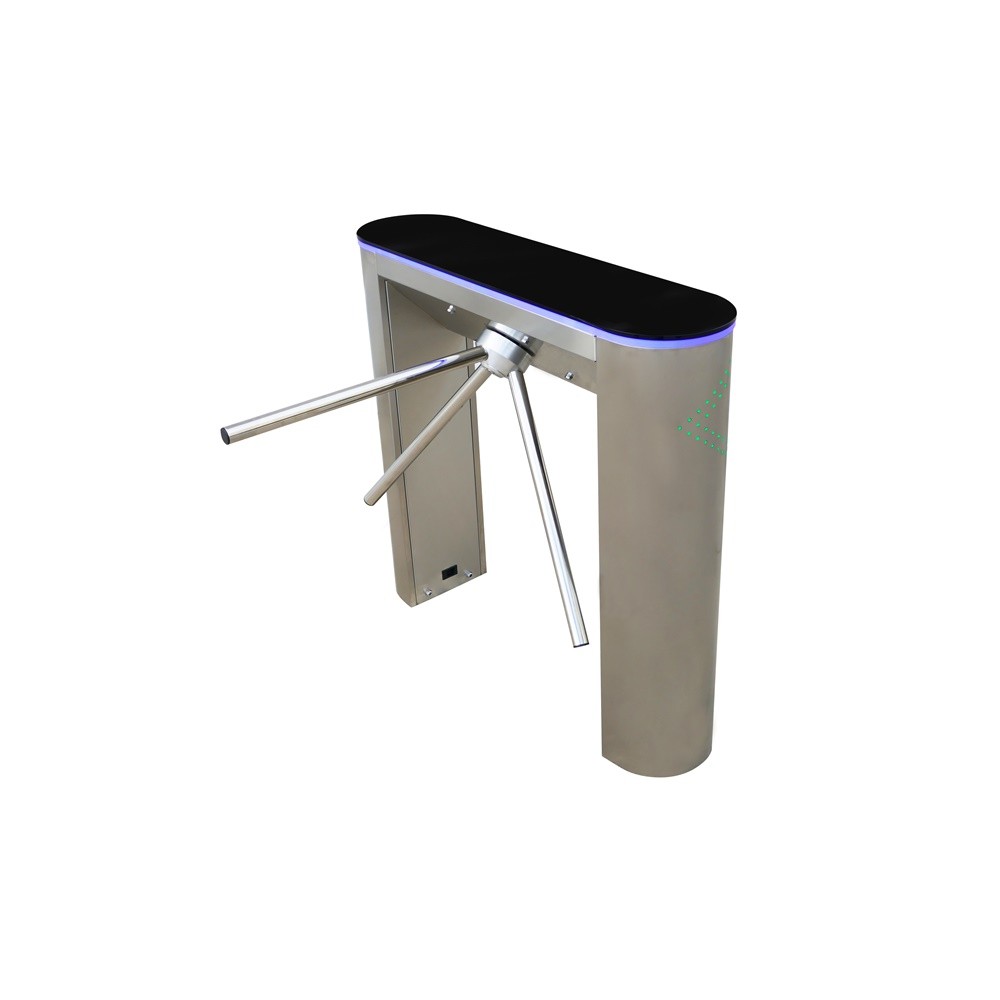

Application :T 250 GT can be installed and used trouble-free in various locations like public transportation terminals, universities, banks, business centers, museums, sport centers and amusement parks etc.

Basic Materials:T 250 GT is produced in AISI 304 stainless steel. All arms and body are made of 304 stainless steel and the core is made of aluminum material against corrosion. T 250 GT has stylish rounded legs. As an option, it can be produced from 316 stainless steel. The inner main mechanism of T 250 GT is produced with special investment casting technology, which makes the whole system a lot more robust and lasting. The electronic boards are designed by the qualified engineers of Makim, enabling T 250 GT operate in various modes and integrations

General Usage: T 250 GT electromechanic turnstile operates bidirectionally. Any kind of access control system like card reader, biometric reader, remote control unit or push button can be integrated to T 250 GT via simple dry-contact. Once the access right is granted, user should touch slightly to T 250 GT arm in order to make it rotate. After the tripods complete one turn, T 250 GT is automatically locked. If the user does not use the passage right in 15 seconds, T 250 GT will give buzzer warning and it will be locked. Status indicator LED lights are located on both sides of T 250 GT, in green arrow and red cross shape to show allowed passage directions. Passage rate is upto 30 person/minute.

Safety:

In case of power cut, T 250 GT is unlocked to allow free rotation of the arms in both sides. As an optional, Makim can produce T 250 GT with drop-arm mechanism. In this case, once T 250 GT receives a signal from the emergency system, the blocking arm will drop to provide a completely free passage lane for quick evacuation of the area.